Ontbreekt er informatie? Omwille van technische informatie, kon niet alle informatie opgevraagd worden, en kan uw aanvraag niet volledig verwerkt worden. Gelieve later opnieuw te proberen. Onze excuses voor het ongemak

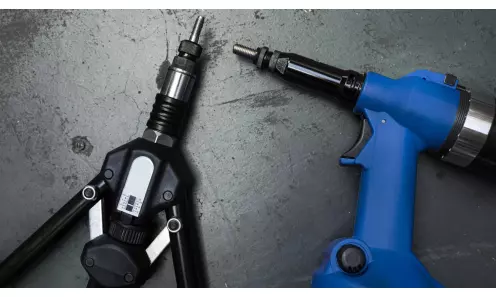

Een Tubtara® blindklinkmoer is een mechanisch bevestigingsmiddel dat met haar sterke schroefdraad en breed gamma aan materialen, vormen en maten uiterst geschikt is voor allerlei toepassingen. Zo worden ze onder meer geplaatst in dunne en dikke metalen platen of profielen alsook in composietmateriaal of kunststoffen.

Ze maken dusdanig tappen, lassen of werken met bouten en moeren overbodig waardoor ze ideaal zijn voor gesloten toepassingen die slechts langs één kant toegankelijk zijn. Als pionier in innovatie en met meer dan 65 jaar kennis aan materialen en productieprocessen op de teller, is Dejond dan ook het juiste adres voor jouw bestelling op maat!